Breadcrumb

- Home

- Contract Services

Contract Services

Some of our state-of-the-art instruments

Fermentors

Biostat D100 DCU3 Fermentor: This equipment is a pilot-scale fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 100 L. Its design incorporates most commonly requested functions and features such as digital measurement and control system, probes for temperature, pH, dissolved oxygen foam, and four built-in peristaltic pumps.

Biostat 1500L Fermentor: This equipment is a large-scale fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 1500 L. Its design incorporates most commonly requested functions and features.

Biostat 75L Fermentor: This equipment is a small-scale fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 75 L. Its design incorporates most commonly requested functions and features.

Biostat C30 DCU3 Fermentor: This equipment is a compact, small-scale fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 10 to 30 L. Its design incorporates most commonly requested functions and features.

Biostat Cplus 30L Fermentors: This equipment is a Sterilizable-In-Place (SIP) fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 30 L.

Biostat Cplus C20-2 Fermentor: This equipment is a small-scale fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 20 L. Its design incorporates most commonly requested functions and features.

Biostat 10L Fermentor: This equipment is a small-scale fermentor system for the cultivation of microorganisms and cell cultures with a volume capacity of 10 L. Its design incorporates most commonly requested functions and features.

Biostat B Control Tower: This equipment is used to control stirred-tank glass or single-use vessels and rocking-motion vessels for fermentation purposes. One control tower can drive one or two culture vessels independently of each other. It is useful for performing batch, fed-batch or perfusion processes for process development as well as production of active pharmaceutical ingredients for preclinical studies or scale-up studies and protein supply.

Centrifuges

Sorvall LYNX 6000 Centrifuge: This equipment is used for centrifugal separation and can perform up to 100,605 x g and up to 6L capacity.

Beckman Optima L-70 Centrifuge: This equipment is used for centrifugal separation that is designed to perform up to 70,000 rpm with centrifugation forces of up to 504,000 g. It can reduce heavy salt precipitation and is compatible with a wide range of high-power rotors. In addition, the unit is compatible with a wide range of high-power rotors.

Beckman J2-MC Centrifuge: This equipment is a high-speed, high-capacity ultracentrifuge that offers precise speed control and high reproducibility used for centrifugal separation. It can protect sensitive samples and delicate gradients.

LAPX 404 Centrifuge: This equipment is a self-cleaning, disc-stack centrifuge with high g force applicable for removing suspended solids with a particle size of 0.5 t0 500 µm used for centrifugal separation. It is configured as a clarifier (solid-liquid) separator or concentrator to separate large volumes of water-based fluid from a small volume of oil, hence suitable for pilot plant, laboratory, and small-scale production. Its scale-up capabilities are also useful for various laboratory purposes.

Sharples AS26 Vertical Centrifuge: This equipment is used for centrifugal separation with a clarifier design, stainless steel bowl, internal cooling coils, 2.1 sg maximum, and 5.3-liter bowl solids holding capacity.

Cell Disruption

Microfluidizer M-110Y: This equipment is a high-pressure laboratory microfluidizer processor for high-shear fluid processing. It maximizes the energy-per-unit fluid volume, resulting in uniform submicron particle and droplet sizes. This system is easy to handle and clean without disassembly. Its flexibility allows for processing of a wide variety of fluids while providing repeatable, uniform results with guaranteed scale-up to full production.

Microfluidizer M-210-EH: This equipment is a high-pressure laboratory microfluidizer processor for high-shear fluid processing. It maximizes the energy-per-unit fluid volume, resulting in uniform submicron particle and droplet sizes. It is easy to handle and clean without disassembly. Its flexibility allows for processing of a wide variety of fluids while providing repeatable, uniform results with guaranteed scale-up to full production.

Fisher Scientific 550 Sonic Dismembrator: This equipment is used to disrupt and rupture prokaryotic and eukaryotic cells during protein and nucleic acid purification protocols. In addition, it is used for efficient mixing in nanotechnology applications including dispersion of carbon nanotubes and polymers.

ÄKTA Chromatography Systems

ÄKTApurifier 100: This equipment is a versatile, modular liquid chromatography system used for the separation of proteins, peptides, and nucleic acids by FPLC. It is designed for purification of microgram to milligram quantities of protein with flow rates ranging from 0.001 to 10 mL/min.

ÄKTAexplorer 100: This equipment is a small-scale protein purification system having flow rates up to 100 mL/min. It is ideal for studying protein interactions, characterizing protein structure, or isolating proteins for further downstream analysis.

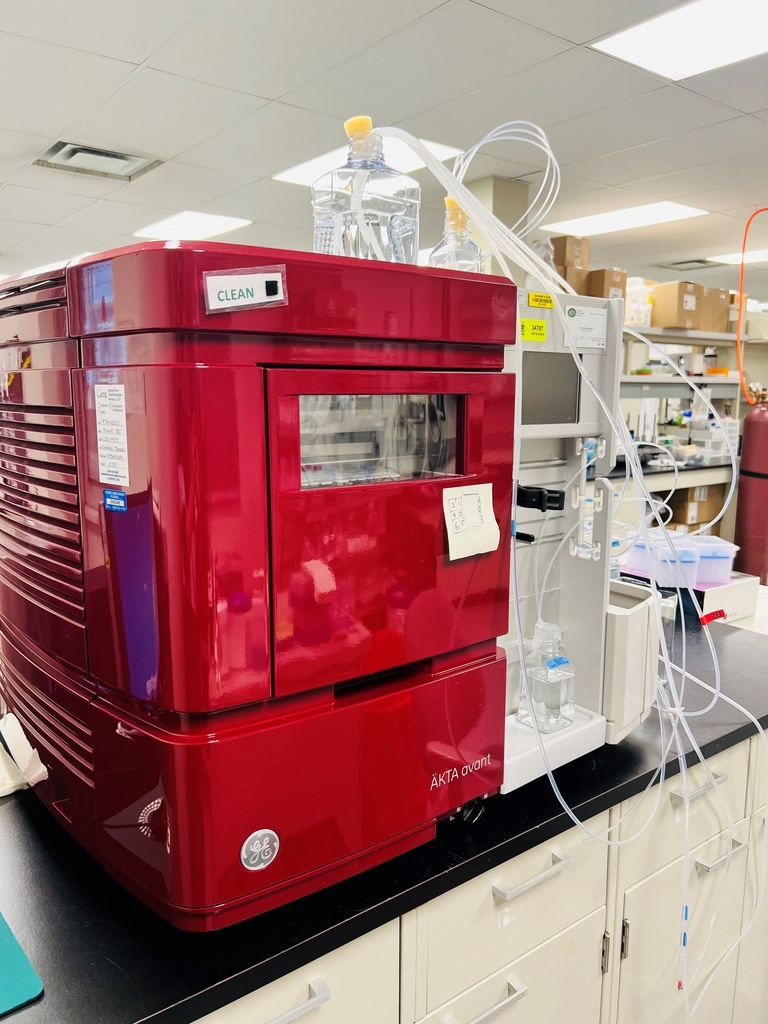

ÄKTA Avant 150: This equipment is a preparative protein purification chromatography system designed for efficient development of scalable methods and processes. This 150 model is designed for scaling up to larger columns, such as HiScale and AxiChrom columns, as well as fine-tuning and robustness testing of the optimized process before moving on to pilot scale.

ÄKTA Process Skid: This equipment is an automated liquid chromatography system built for process scale-up and large-scale biopharmaceutical manufacturing. With 10 mm skid that allows a range of flow rates from 15 L/h to 600 L/h, it is useful for scaling up processes developed with smaller ÄKTA systems such as ÄKTAexplorer and ÄKTApilot.

ÄKTA pilot 600: This equipment is a compact bench-top chromatography system used in both non-GMP and GMP environments. It can handle a range of flow rates from 0.1 to 1200 mL/min, making it suitable for both production of technical batches and scale-up studies as well as small-scale production of GMP-grade material.

Spectrophotometry

Shimadzu UV-2401 UV-Vis Spectrophotometer: This equipment is a standard research-grade UV-VIS spectrophotometer capable of scanning from 190-900 nm. The software of this spectrophotometer is capable of acquiring data in spectrum mode, photometric mode, and kinetic data.

Mettler Toledo UV5Nano Spectrophotometer: This equipment is used for qualitative and quantitative analysis with 1-2 µl protein or nucleic acid samples. It is useful for concentration and purity determinations using A280, A260, A260/A280, Bradford and BCB protein assays, and so on. This equipment also allows cuvette measurements.

Bio-Rad SmartSpec Plus: This equipment is a scanning tabletop UV-Vis spectrophotometer used for routine quantitation of protein and nucleic acid samples. With a working wavelength range of 200-800 nm, it allows for the quantitation of proteins using UV, Bradford, Lowry, and BCA assay methods as well as simple kinetic assays. It is capable of simple calculations such as A260/A280 ratio for nucleic acid purity, sample concentration in mg/ml, µg/ml, and pmol/µl or molar extinction coefficient and molecular weight of oligonucleotides.

Gel Imaging

Bio-Rad GS900 Densitometer: This equipment is designed to reproducibly image gels, blots, and film and quantitate proteins across a wide dynamic range. It uses transmissive and reflective imaging to scan chromogenic samples at the optimal detection wavelength. With the three-color red, green, and blue CCD imaging technology, this equipment enables accurate, reproducible quantitation with a wide variety of common stains.

Sterilizers

Beta Star Sterilizer: This sterilizer is specifically engineered to meet the FDA’s stringent compliance requirements for Current Good Manufacturing Practice (cGMP). The sterilizer is outfitted with a range of cycle options including isothermal, air-over-pressure, and BSL-3 effluent.

Steris Amsco Stage 3 Gravity Steam Sterilizer: This equipment is designed for sterilization of liquids in flasks with vented closures, along with heat and moisture-stabile goods. The gravity units are operated based on the gravity downward displacement air-removal principle.